FEA is the acronym for ‘finite elements analysis.’ Based on the finite element method (FEM), it is a technique that makes use of computers to predict the behavior of varied types of physical systems, such as the deformation of solids, heat conduction, and fluid flow. FEA software, or FEM software, is a very popular tool used by engineers and physicists because it allows the application of physical laws to real-life scenarios with precision, versatility, and practicality.

In this article, we discuss the basic questions you have about FEA as a beginner and provide you with links to all the necessary references you need to understand and start using FEA today.

Set up your own cloud-native simulation via the web in minutes by creating an account on the SimScale platform. No installation, special hardware, or credit card is required.

FEA is the application of the finite element method (FEM) to practical problems. The finite element method is a mathematical procedure used to calculate approximate solutions to differential equations, allowing for its application to real engineering problems. The goal of this procedure is to transform the differential equations into a set of linear equations, which can then be solved by the computer in a routine manner.

Differential equations are very important and present in many engineering problems because they represent the language in which physical laws are expressed. They connect changes in the internal variables of an object, such as displacement, temperature, or pressure, and their relation with the object’s geometry, physical properties, and external influences acting on it.

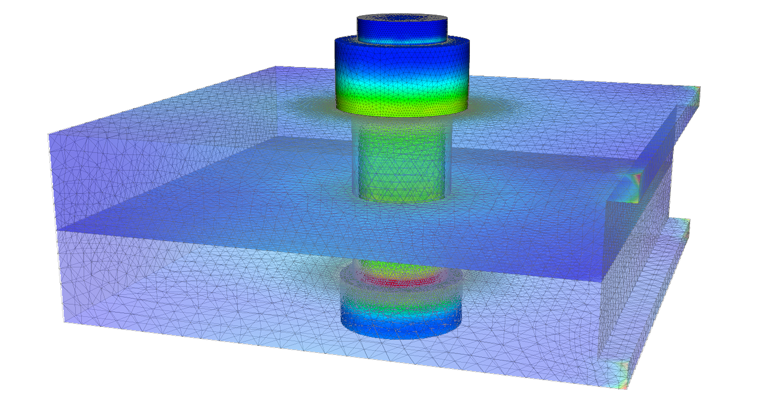

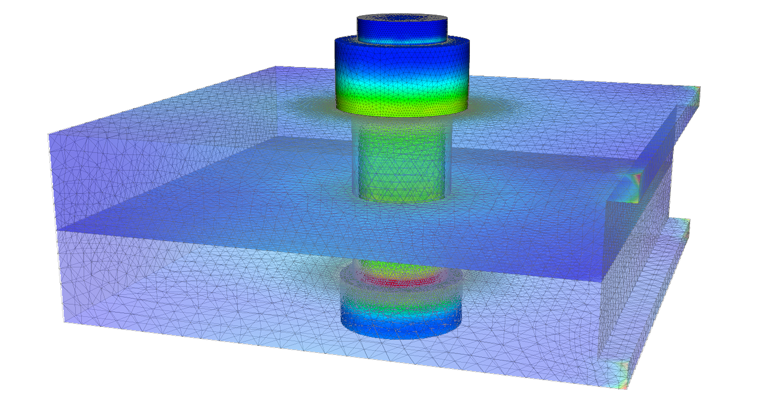

The detailed explanation of how this transformation from a physical law into a set of linear equations is performed is beyond the scope of this article, but here is a general overview of the process:

For more information on how FEA works, check out our guide to FEA by clicking the button below.

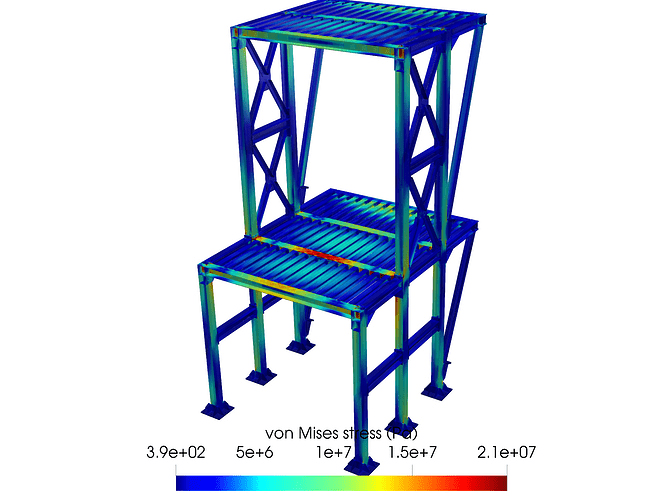

Although the finite element method is not bound to a particular type of physical problem, its main field of application is the structural analysis of solids. Structural analysis might include different types of loading and scenarios, but its main purpose is one: to predict whether a given part or structure will safely withstand forces acting on it.

This is achieved—according to the theory of the resistance of materials—by looking at the state of the part in terms of stress and strain. The maximum values obtained by any method (for example, FEM) are compared to allowable values to see if they conform to the safety range. These allowable values are most of the time specified by a design code such as ASCE, ASME, Eurocode, etc.

Some typical use cases of FEA software include:

For more information on use cases of FEA, click the button below to read about FEA in SimScale and some example cases.

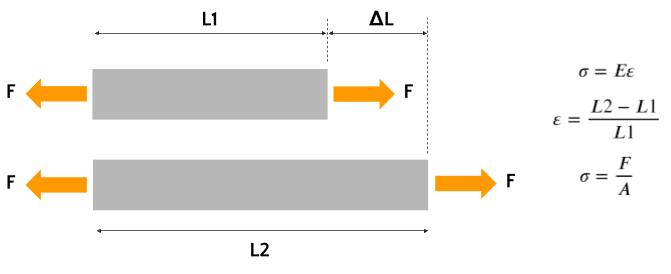

Two very important concepts to grasp in order to start using FEA for structural assessment are stress and strain, as they are both related to the deformation of solid bodies. These topics are typically covered in depth when learning about the strength of materials, but here we will give a brief introduction.

When a solid body is subject to the action of external forces, such as pressure, contact, or gravity, the body will undergo some deformation. The shape and magnitude of such a deformation depend on many factors, such as the direction and magnitude of the external actions, the geometry of the body, and the rigidity of the constitutive material.

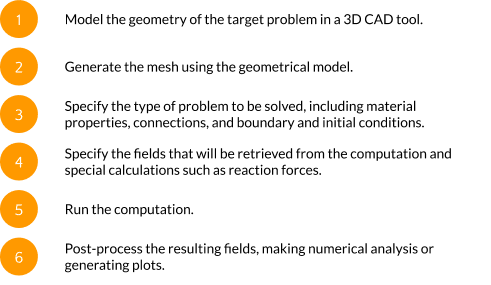

The simplest example of this is the deformation of a spring: when the spring is hung in a vertical position, it is in equilibrium with some characteristic length. If weight is attached to the lower end, the spring will extend, up until reaching another equilibrium point, this time with a longer length.

If the magnitude of the weight is varied, we will notice that the elongation of the spring is proportional to the weight, also known as Hooke’s law, and the constant of proportionality is known as the spring’s ‘rigidity.’

What happens internally, is that the external forces are balanced by forces developed inside the material, which tends to oppose the elongation effect, causing the equilibrium state. These internal forces are known as the material’s ‘stress‘ and are the result of cohesive forces at molecular levels. The higher the activity of the external force, the higher the stress developed by the material will be. Failure theories are based on limit stresses, that is, failure of the element is expected to occur when stress levels surpass a given threshold.

When trying to write Hooke’s law in terms of material stress, one notices that the elongation of elements is not a consistent measure. If the geometry of a test specimen (e.g., for a uniaxial test) is changed, then the rigidity constant does not generalize for a given material. A special measure of deformation should be considered. This is known as the material ‘strain‘ and has a few different definitions, such as ‘engineering strain‘ or ‘true strain.’ These definitions allow us to state a relation between the material’s stress and strain, using a measurement of the material rigidity known as Young’s modulus.

Although stress and deformation are the main calculations in FEA, they are not the only important predictions that can be made with it. Other very useful information for a given structural system that can be obtained with FEA include:

For more information on stress and strain in FEA, click the buttons below to read about different aspects of stress and strain.

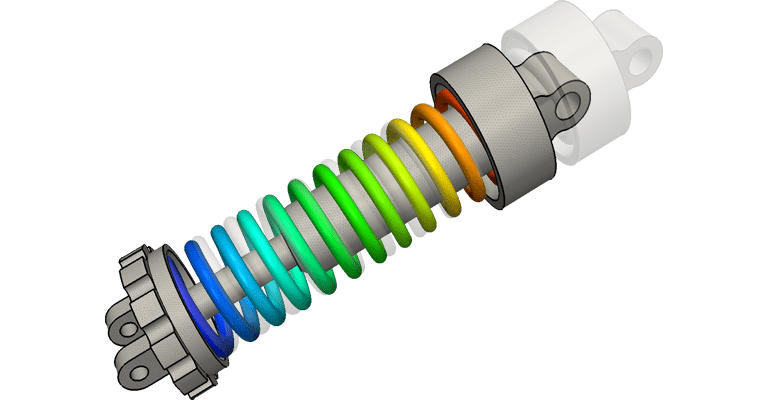

In the automotive industry, FEA software simulations are performed to assess the structural safety of designed components, such as chassis, anchors, suspension, bodyworks, etc. One of the most interesting applications is virtual crash tests, where a dynamical simulation is performed to predict deformations and energy absorption against crash impact. Here is a SimScale project simulating a car suspension’s deformation and stress .

For more information on the automotive industry, click the link below.

For more information on the architecture, engineering, and construction (AEC) industry, click the link below.

FEA is the defacto technology for detailed stress analysis and deformation prediction across almost every engineering field. As more analysis tools become accessible to designers and engineers, it has a lot of space to grow its presence. As we have been able to see, it is very versatile and powerful, making it a must-have tool in any product design portfolio.

The most recent trend in FEA software is cloud-native simulation services and tools. Companies such as SimScale provide simulation tools that run in the web browser and make use of remote servers for the computing tasks, freeing local resources, and lowering the requirement for powerful hardware and special software installations.

Explore FEA in SimScale